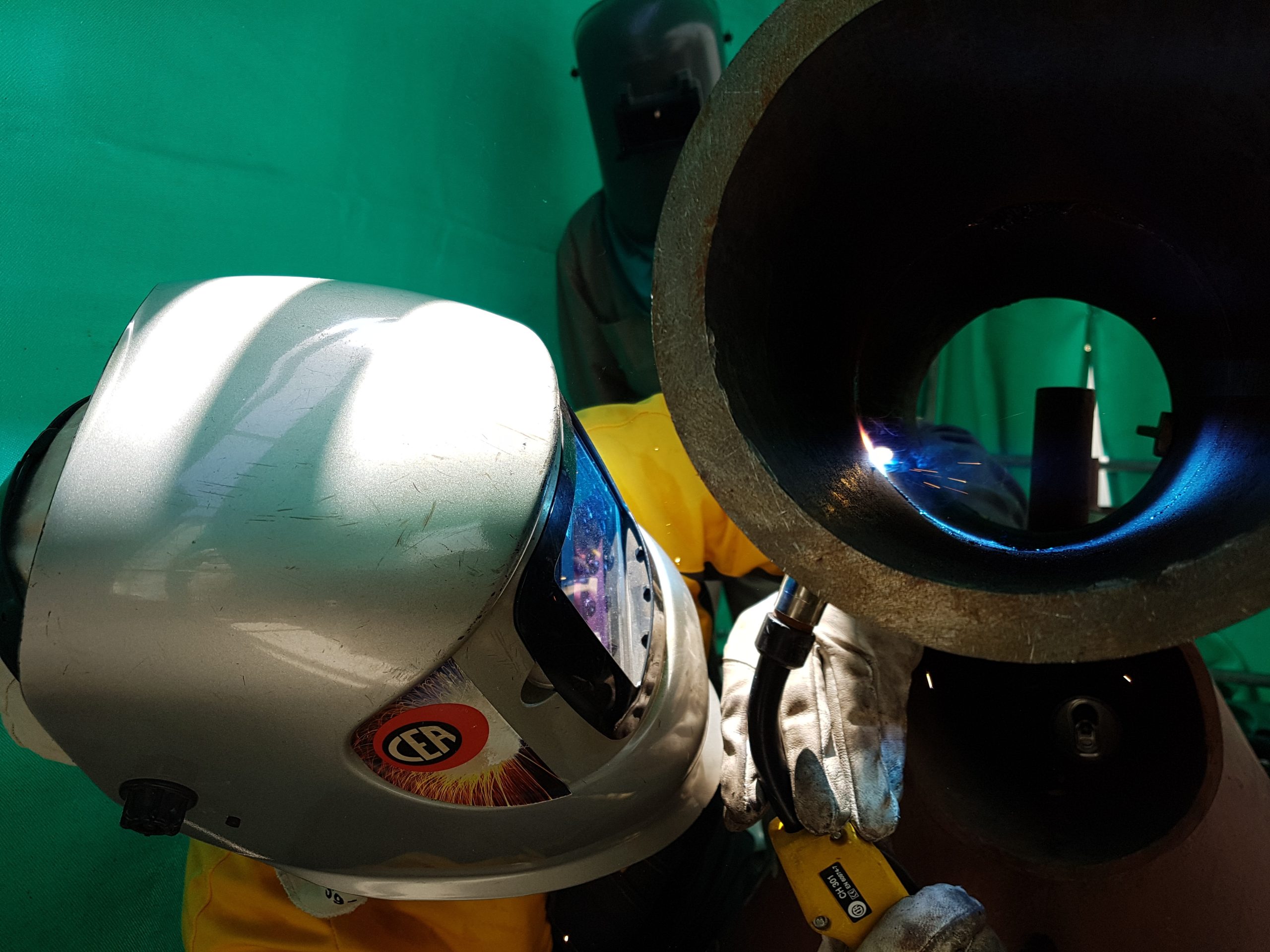

The special processes designed by CEA for different types of welding

CEA’s long experience, listening to customer needs and their consistent investments in R&D, have given rise to a series of special processes that make welding easier, even when having to tackle special situations like a vertical bead or the need to work well and fast.

These are what enable CEA welding machines to use these special processes for various types of welding: the advanced vision.ARC and vision.ARC2. The latter was designed for those users who also need special pulsed processes.

If you want a FREE DEMO of our products or need some information click here! We're at your service!

Vision.ARC and Vision.ARC 2: the advantages of MIG MAG welding in TIG welding

This software created by CEA is inserted in arc welding machines, not just to manage special processes, but also to control arc stability and correct the pulse in the pulsed welding process.

Vision.ARC and Vision.ARC 2 in MIG MAG welding machines provide significant advantages:

- Reduced heat input

- Increased speed in the welding process

- Improved arc stability

- Greater pulse control

- Quick control of short-circuits in case of welding with a very short arc

The software created by CEA can manage the following special processes:

- COLD (available also for Vision.ARC)

- ULTRASPEED (available also for Vision.ARC)

- POWER (available also for Vision.ARC)

- PIPE (available also for Vision.ARC)

- PULSE-UP

- PULSE-RUN

- PULSE-POWER

The last three special processes added to the list were specially designed for pulsed welding.

All these innovative processes enable raising the quality of the welds and to assist less skilled operators as well.

When you need MIG MAG welding with low heat input: vision.COLD Welding process

The vision.COLD process was designed for welding thin sheet metal and for all work where a high heat input could cause the piece to deform; it’s also ideal for MIG brazing in any position.

vision.COLD provides many advantages and unique features, such as:

- Ability to weld thin carbon steel and high alloy steel sheet metal

- Increased speed in joint welding

- No spatter in case of short-circuits

- Decreased heat input and deformations

- Decreased damage to galvanised sheet metal in MIG brazing

- Precise melting of edges in vertical welding

Vision.ULTRASPEED Welding process for fast and precise work

To speed up the welding process for steels and non-ferrous materials, vision.ULTRASPEED was designed.

The increased speed is provided by the increase in the arc’s magnetic force and a more restricted arc cone.

This process designed by CEA has the following main advantages:

- Increased work speed by over 50%

- Possibility of welding medium-thickness pieces in carbon steel and stainless steel, aluminium

- Creation of narrow beads, saving filler material and gas

- Reduced heat input

- No ejections or spatter when depositing the wire

High penetration of medium and thick sections with vision.POWER welding process

MIG MAG welding of pieces with medium/thick sections that require high penetration is much easier when using the vision.POWER function.

The narrow welding arc generated by this special process ensures greater pressure and thus greater penetration.

Other advantages are:

- Saving on filler material, shielding gas and current

- Increased speed compared with MIG MAG spray-arc welding

- Reduced heat input

- Elimination of hot cracks

- Lower number of passes, thanks to the smaller size of the bevel edge

- Decreased possibility of inclusions

- No porosity or blow holes

- No overfill in butt joints

- No spatter or ejection issues

The initial pass on pipes and sheet metal is easier thanks to vision.PIPE Welding process

The vision.PIPE process is what you need when you have to do the initial pass with MIG or MAG in butt joints on pipes and sheet metal, even with gap.

The main advantages are:

- Increased speed compared with TIG and MMA welding

- Precise welding in all positions and any thickness

- Decreased heat input on joints

- Precise melting of edges in vertical welding

- Ease of use, even for less skilled operators

- Root welding without support systems (backing)

The solution for vertical-up welding: vision.PULSE-UP Welding process

With this function expressly created by CEA, it is possible to make perfect vertical-up welds without using the so-called Christmas tree pattern technique.

The advantages of vision.PULSE-UP are:

- Increased work speed by 40%

- Perfect melting of the root

- Welding of thin sections with low heat input

- Faster root pass than TIG welding

Vision.PULSE-RUN Welding process combines pulsed welding and speed

Welding steel alloys and non-alloys and aluminium is now faster thanks to this process, which takes advantage of the features of Pulsed MIG welding and the above-mentioned vision.ULTRASPEED.

The advantages of these two technologies combined together are:

- Increased speed by 40% compared with traditional pulsed

- Reduced deformations, especially in stainless steel

- No ejections or spatter

- Greater control of the weld pool

- Increased penetration

Vision.PULSE-POWER Welding process combines pulsed welding and penetration

The merging of Pulsed MIG and vision.POWER has given rise to this process, that simplifies high-penetration welding of non-ferrous materials and steels with medium/thick sections.

Other major advantages are:

- Creation of beads with no defects and well-shaped, with high penetration

- Increased speed

- Lower heat input and fewer distortions

- Saving on filler material and shielding gas

- Easier welding method without torch manipulation

{{cta('c9819577-65d8-4853-80d0-e1a00c4511b7','justifycenter')}}