New synergic welding systems: quality and rapid welding

Human control alone is no longer enough in precision industrial processing where instruments such as welding machines are used. Only highly specialised workers can continue using manual welding machines, but this entails a high cost to companies where many high-skill welders need to be employed in the production line.An unskilled welder could make mistakes and slow down the whole work process, inevitably causing delays in deliveries and a rise in costs.

Today, the issues due to human error in welding are much lower thanks to technologies that make these machines synergic.

A synergic welding machine helps the worker not make mistakes, work quickly and with always-high quality standards.

If you want a FREE DEMO of our products or need some information click here! We're at your service!

TIG Welding and MIG/MAG with synergic welding digital generators

By now, industry 4.0 is a well-known topic to anyone running a company. The results that this fourth industrial revolution promises greatly depend on the progress of automation technology and the digital intelligence applied to machinery, which will provide and independently manage all the information concerning the work process.

When welding can no longer be delegated to a robot, but must be made by a worker in flesh and blood, then the man/machine synergy is essential to achieving excellent results.

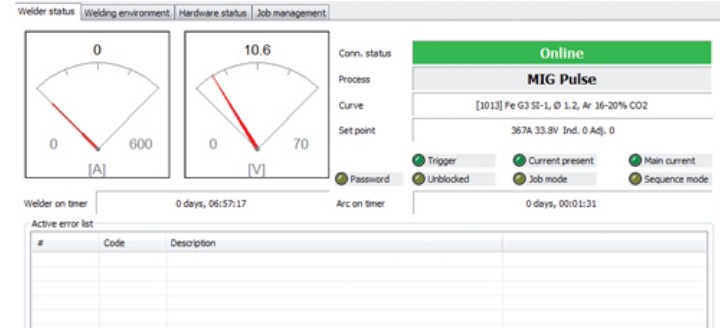

TIG and MIG/MAG welding machines are even more flexible in professional use when they have a digital mind that can guide the welder in using the right welding parameters.

The most advanced digital generators for welding can have selectable memories where all the settings are ready to go, depending on the material to be welded, the thickness of the wire used, and the gas chosen to shield the weld pool from oxidation.

With these synergic welding machines, perfect beads can be made, quickly, even with less specialised welders.

More expert welders can also take advantage of the features of a synergic digital welder, setting custom welding parameters to hone and speed up their work even more, achieving perfect welds.

Read also: " Synergic inverter welding machine: the CEA welding solution in Qubox "

The software that leads to welding in the future

What truly makes a welding machine synergic, is the software that manages it.

In addition to storage and the intuitive selection of programs with pre-set welding parameters, the software of digital generators for welding designed for industry 4.0 can:

- Stabilize the arc

- Reduce the heat input

- Optimize the pulse

- Speed up the welding process

- Control droplet detachment in pulsed MIG welding

- Control the overall operation of the machine

- Save on current, filler material and gas

- Limit distortion on thin sheet metal

Read also: " Robotic welding: 5 good reasons to buy high-tech welding machine "

The quality of the welding is assured with synergic welding machines when the software can also manage functions designed specifically to resolve common issues in the welder’s work.

There’s also the increased speed, of course. Synergic welding systems with special welding programs can register up to 40% and 50% in saved time compared with traditional welding methods.

{{cta('532b36ee-205a-4d91-b6e2-8b4fa9348164','justifycenter')}}